Large electrical power roller chains with improved fatigue strength and influence power

HI-PWR-S roller chains are enhanced in fatigue power and impact strength without the need of altering the dimension inside the pin length route of regular roller chains. Plates are enlarged, as well as machining accuracy and assembling accuracy of components are improved. The roller chains hold high transmission efficiency for applications from low to large speeds and therefore are impressive sufficient to stand up to long-term use.

Encouraged uses

?Compared to standard roller chains, HI-PWR-S roller chains are increased in optimum kilowatt rating by about thirty % inside a medium to very low speed assortment. They exhibit fantastic capability in places exactly where big shock loads are utilized, drive units for frequent start/stop, as well as in large speed applications.

?Civil engineering machines such as skid steer, trenchers, trucks, cranes, agitating trucks, forklifts and drive units for conveyors, elevators, stackers, and so on.

Selection of chains

Normally, select your chain with reference to “Designing of Chain Transmission” as well as to your tables of “Drive Performance” and “Dimensions” of HI-PWR-S sort roller chains.Having said that, only for a special case of low pace and less shock, “Low-speed selection” can also be applicable.

Sprockets

HI-PWR-S Roller chains and ANSI normal chains  would be the very same in essential dimensions. Use ANSI regular sprockets.

would be the very same in essential dimensions. Use ANSI regular sprockets.

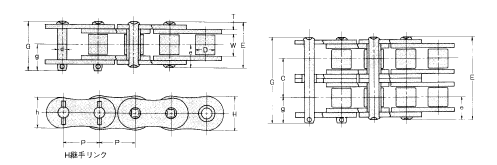

Connecting hyperlinks and offset hyperlinks

Use H connecting backlinks for HI-PWR-S. In an H connecting link, the pins are lightly interference-fitted together with the connecting plate. To the connection amongst the connecting plate and also the connecting pins, spring pins are utilized in place of cotter pins for any common roller chain.

The center plates of an H connecting link for multiplex chain has bushings pressed in.

HI-PWR-S roller chains do not have any offset link. Use an even number of links.

Hardly ever make the holes of the connecting plate larger and never ever make the pins thinner to facilitate the work for fitting the pins into the connecting plate, given that otherwise the fatigue strength will probably be lowered.