Factors Affecting Variety

The next is usually a listing of your details important to assist in generating a coupling choice. Not all of those things will come into perform in all choice processes. These goods incorporate, but are certainly not constrained to:

Application linked:

Application details

Sort of motor and driven tools

Motor horsepower or KW

Operating/coupling velocity

Shaft sizes and separation

Room and dimension constraints

Surroundings (temperature, chemical substances, and so forth)

Stability demands

Exclusive modifications

Steps In Choosing A Gear Coupling

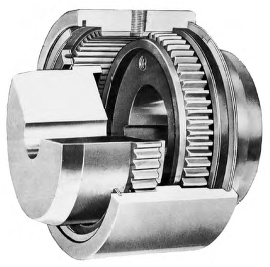

Refer to the gear coupling specs charts displayed with each and every form of coupling through the entire Gear Coupling Merchandise segment of this catalog. The images and charts give visualization, specs, and dimensional data for its wide variety of gear coupling items. Generally start with an F Style flanged gear coupling or even a C Type continuous sleeve gear coupling (web page G-16) and proceed from there.

Stage one: Overview the gear coupling series and  sort as picked to guarantee the variety

sort as picked to guarantee the variety

meets application demands.

Stage 2: Identify the nominal application torque in in-lbs by using the following formula:

Application Torque ( in-lb ) = (HP x 63025)/RPM

Or Nm = (KW x 9550)/RPM

Phase 3: Critique the Application Service Issue chart for that services element quantity linked with all the application where this coupling are going to be used. Multiply the application torque by the application service aspect to find out the complete torque required for the coupling choice.

Phase 4: Review the needed complete torque value using the nominal torque capability

listed inside the Gear Coupling Assortment chart for that sought after coupling form.

Phase five: Examine the maximum bore dimension as well as the greatest RPM of your coupling

style picked to make sure the coupling will meet these application necessities.

Stage 6: Note any distinctive necessities including the BSE dimension for floating shaft and spacer styles, shear pin torque, slide coupling information, mill motor tapered shaft data, and any other pertinent information and facts.